Plastic additives are widely used in packaging materials to enhance the performance of packaging materials, making them more suitable for use in a variety of commodity packaging.

Antifogging agent

Antifogging agent, also known as drip agent, is a plastic additive that can effectively prevent fogging on the surface of non-hydrophilic objects. According to the way of adding it, it can be divided into two types: internal type and external type. The use of anti-fogging agent will not affect the light transmission performance and performance of the film. Antifogging agents are also an auxiliary agent developed with the research of agricultural films. However, in recent years, it has also been used in plastics for refrigerating foods and fruit and vegetable packaging, and has a positive effect on reducing water vapor condensation in the packaging film and increasing the transparency and visibility of the contents.

Deoxidizer and UV blocker

Deoxidizers and UV blockers are new and emerging additives in recent years. The deoxidizer can absorb oxygen in the package, reduce the damage of environmental oxygen to the contents, and prolong the storage time of the food; the ultraviolet blocker can block the ultraviolet rays, avoid the damage of the ultraviolet rays to the contents, and prolong the storage period of the product. These two types of additives are mainly used in packaging products in the fields of food, medicine, health care products and cosmetics.

Thermoforming Pvc Roll Rigid Sheet is most commonly used for plastic moldings where it is injected into a mold while molten, forming complex shapes at relatively low cost and high volume, examples include bottle tops, bottles and fittings. It can be used as blister packaging rigid PVC sheets.

PVC is ideal in high corrosive and fire resistant signage applications. With its high chemical resistance, Rigid PVC is highly suitable for industrial applications as well.

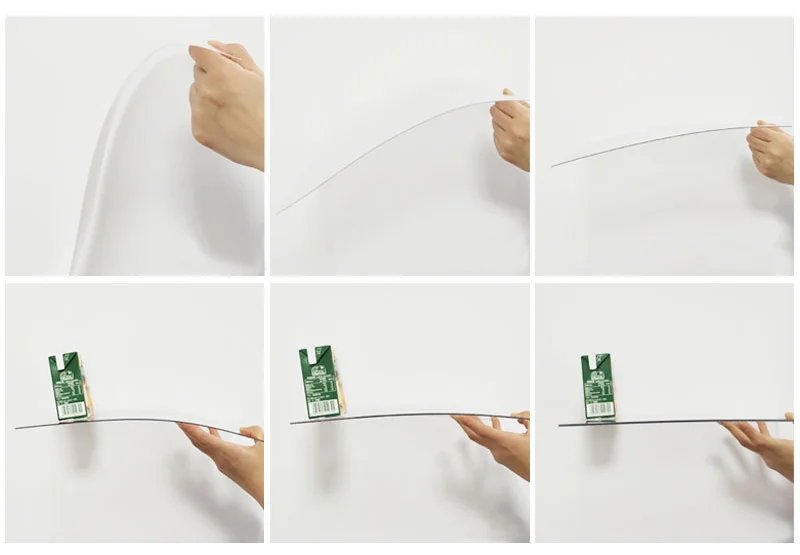

Hardness Test(0.25mm/0.5mm/1mm/1.5mm/2mm/3mm)

Multiple thickness,With good strength and the extensions. We can make sheet or roll for you.

Normal Thickness: 0.1mm -10mm

Normal size : 1220*2440 /915*1830mm /700*1000mm /or Customize.

Surface: glossy,matt,frosted,embossed or Customize.

|

Thickness Tolerance

|

According to GB(higher than GB)

|

|

Density

|

1.3-1.5 g/cm3

|

|

Tensile-Strength(lengthwise,crosswise),MPa

|

≥52.0

|

|

Impact strength(cut)(four-way)KJ/M2

|

≥5.0

|

|

Drop impact strenght

|

No fracture

|

|

Vicat softening piont,°C

Decoration plate

Industrial plate

|

≥75.0

≥80.0

|

|

Heating size change rate, %

Lengthwise

Crosswise

|

-5.0--+5.0

-3.0--+3.0

|

|

Width

Length

Diagonal line

|

Deviation 0-3mm

Deviation 0-8mm

|

Application

|

For Silk Screen Printing

|

For UV Offset Printing

|

For Digiting Printing

|

|

For Vaccum Forming

|

For Thermo forming

|

For Cold / Hot Bending

|

|

For Bending Covers

|

For Blister Packing

|

|

|

For Anti-Static Machine Cover

|

For Playing Cards

|

For Lampshade Cover

|

|

For Furniture/Door Panel

|

For Clothing Template

|

For Adverting Board

|

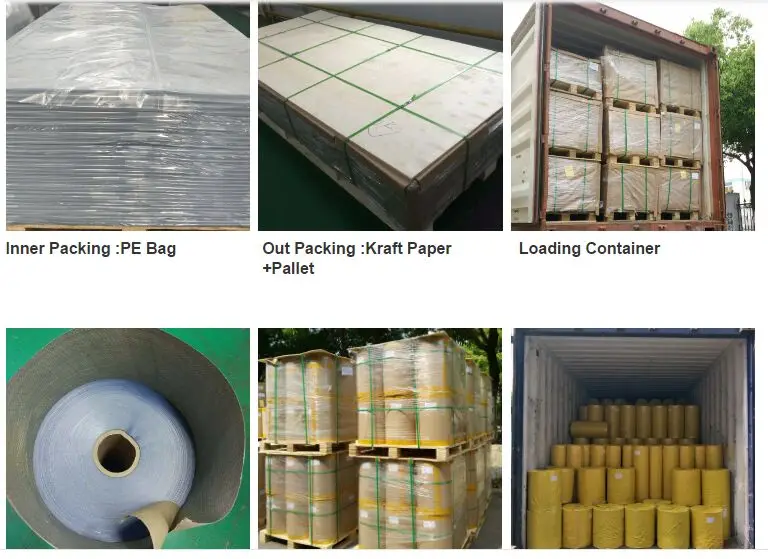

Product packaging

Package:

Wooden pallet, PE film, Craft, PP packing belt

Shipping:

1. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

2. Customers specifying freight forwarders or negotiable shipping methods!

3. Delivery Time: 7 days for batch goods.

Supply 100% QA inspection before delivery

Supply free exporting packing to protect your ordering

Supply free replacement if unsatisfactory material quality

PVC Film

Pvc Rigid Film,Pvc Film In Roll,Packaging Pvc Film,Folding Box Printing Film

Shandong Top Leader Plastic Packing CO., LTD , https://www.sdzlplastic.com